Did the Industrial Revolution decrease costs or increase quality?

Technology moves the efficient frontier

An oversimplified story of manufacturing progress during the Industrial Revolution is: “we automated manufacturing processes, and that decreased the cost of goods.” This is not wrong, but is not the full picture.

Mechanization—and other progress in manufacturing, such as improved tools, materials, and chemical processes—not only decreases costs, but also improves quality. Making things by hand requires skill and attention: just try making your own clothing or furniture at home; on your first attempt you won’t be able to achieve nearly the quality you can purchase for a modest price. Automation not only improves average quality, but also consistency, by reducing variance.

If we want a fuller picture of how goods were improved through the Industrial Revolution, we should think of cost and quality together. We can visualize this conceptually on a two-dimensional chart. Here, each dot represents one possible manufacturing process for a particular good:

In this chart, you want to be in the upper left: high quality at low cost. So there’s no point in using any given process if there is another process that achieves higher quality and lower cost at the same time. This means the industry tends to move towards the set of processes along the upper-left edge. This set is known as the efficient frontier:

If you’re in the middle of a diagram like this, you can improve both cost and quality together by moving towards the frontier. If you’re on the frontier, you face a cost-quality tradeoff.

The nuanced way to think about new technology is not that it simply decreases cost or increases quality, but that it moves the frontier.

Consider cotton thread, one of the first products whose manufacturing was automated. In the late 1700s, spinning machines were invented that could do the work of dozens of hand spinners. Large factories were set up, driven by water mills (and later, by steam engines). Here’s what happened to the cost of thread as automation took over the industry:

Harley, “Cotton Textile Prices and the Industrial Revolution” (1998)

The chart above shows prices for three different grades of thread. Higher numbers indicate finer thread, which makes for softer fabrics.

Conceptually (not to scale), we can visualize what happened like this:

Note that the price for the highest-quality thread, 100 twist, came down most dramatically. It’s possible for humans to spin thread this fine, but it’s much more difficult and takes longer. For many uses it was prohibitively expensive. But machines have a much easier time spinning any quality of thread, so the prices came closer to equal.

At one level, this is a cost improvement. But don’t assume that the effect for the buyer of thread is that they will spend less money on the same quality of thread. How the buyer responds to a change in the frontier depends on the cost-quality tradeoff they want to make (in economics terms, their elasticity of quality with respect to cost). In particular, the customer may decide to upgrade to a higher-quality product, now that it has become more affordable.

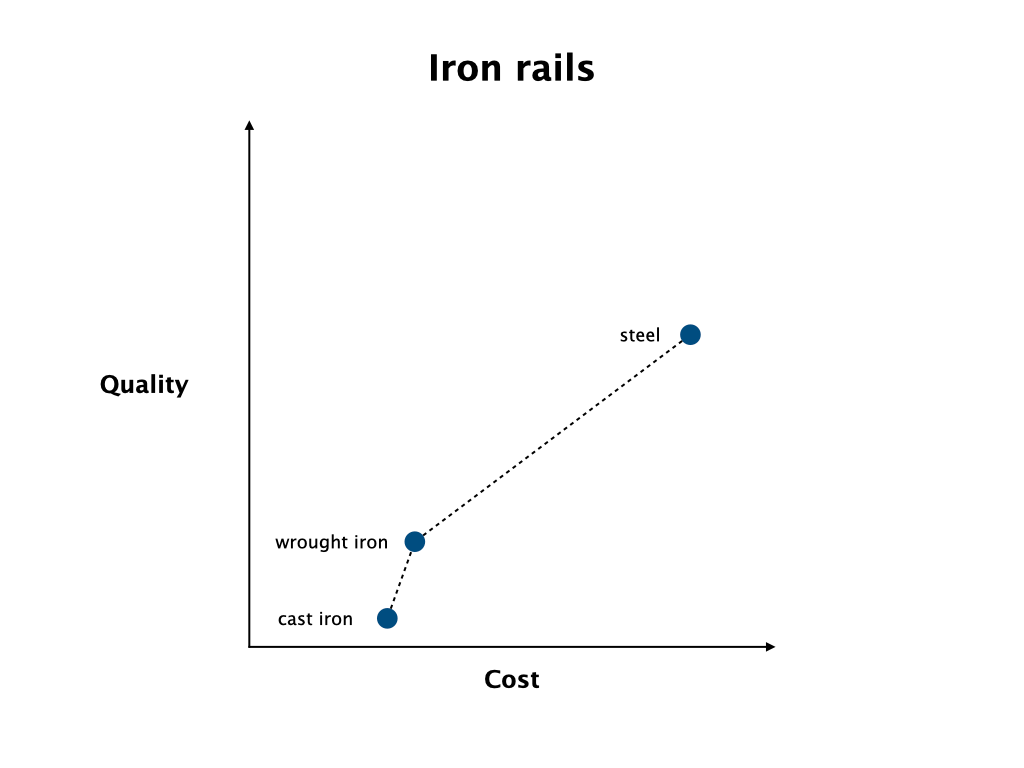

This is what happened in the case of iron, steel, and railroads. In the early decades of railroads, rails were made out of wrought iron. They could not be made from cast iron, which was brittle and would crack under stress (a literal train wreck waiting to happen). But wrought iron rails wore out quickly under the constant pounding of multi-ton trains. On some stretches of track the rails had to be replaced every few months, a high maintenance burden.

Steel is the ideal material for rails: very tough, but not brittle. But in the early 1800s it was prohibitively expensive. The frontier looked like this (again, this is conceptual, not to scale):

Then the Bessemer process came along, a new method of refining iron that dramatically lowered the price of steel. Railroads switched to steel rails, which lasted years instead of months. In other words, what looks like a cost improvement from the supply side, turns into a quality improvement on the demand side:

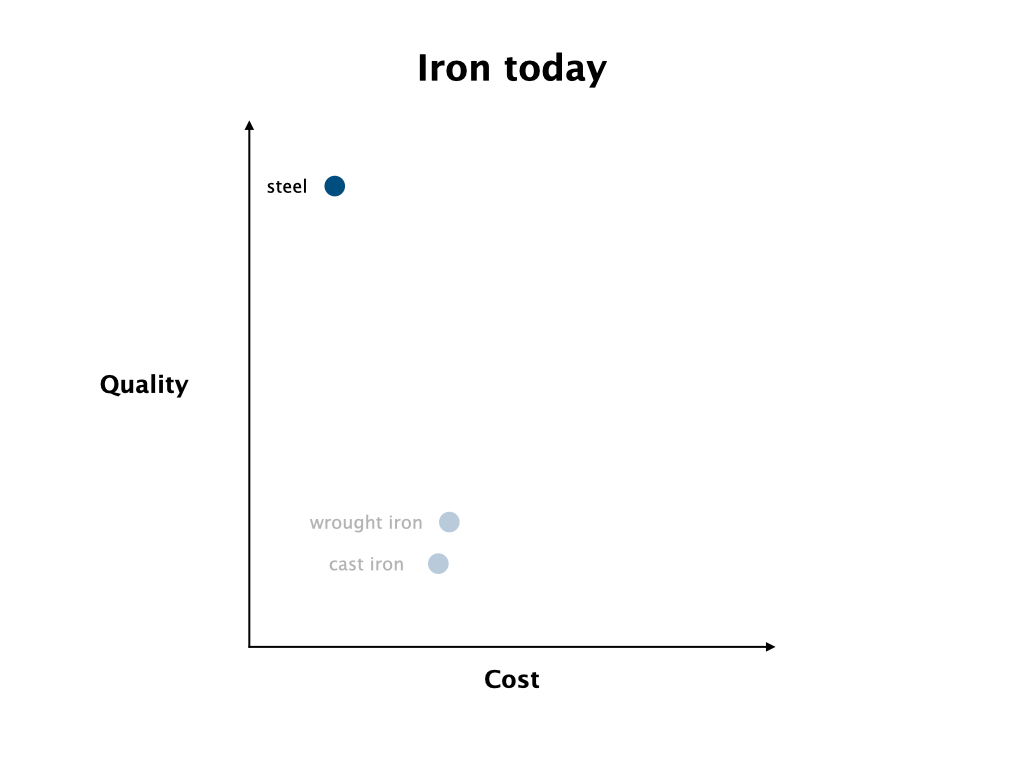

But what was the effect of upgrading to steel rails? A greatly decreased need for replacing the track lowered the operating costs of the railroad. So the full picture looks like this:

In other words, cheaper steel meant cheaper train travel—but not because the railroads could buy cheaper rails. Rather, cheaper steel allowed them to buy higher quality rails, leading to cheaper travel.

The lesson is that whether a new process is an improvement in cost or in quality can change as you follow the links of the value chain.

Another example is that of interchangeable parts. Consider gunsmithing. A gun is made from many parts. The parts have to fit together well enough that the gun works smoothly and reliably. But in pre-industrial craftsmanship, the trigger, for instance, of one gun wasn’t expected to fit any other gun.

On the face of it, this didn’t pose much of a problem for most machines, such as locks or watches, but it was an acute problem for guns, because of the need for field repair. If your trigger breaks while out on a campaign, you can’t repair it until you can get it to a gunsmith. Until then, all you have is your bayonet, and your rifle is just a funny-looking and not particularly aerodynamic spear. At one point in 1811, the British Army had 200,000 useless muskets awaiting repairs.

A better system is to make the parts to better precision, to the point where they are interchangeable. Then if your trigger breaks, you just fetch another out of a box of triggers.

Like fine thread, it was possible for craftsmen working with hand tools to make interchangeable parts. It required precise model parts, jigs, or other guides, and a lot of checking and filing. Check your part against the guide, file it down a bit if needed, check it again. Filed it too much? Toss it out and start over with another part. This was prohibitively expensive for most applications.

The breakthrough came when higher-precision metalworking tools, known as “machine tools,” were invented. Among other advances, these tools did not rely on the worker holding either the part to be worked or the cutting edge by hand: both were clamped down and controlled by screws, gears and dials. As with thread, this increased both quality and consistency.

Fairburn's Self-acting Radial Drill. Record of the International Exhibition, 1862

Machine tools reduced the cost of interchangeable parts. For the army, buying expensive field-repairable guns, this was a direct cost savings. But other manufactured products upgraded from low-precision parts to interchangeable ones, now that the latter had become more affordable. Why? Because interchangeable parts are faster to assemble. Before, final assembly required filing parts to fit if they didn’t line up just right. Interchangeable parts eliminated the need for this, speeding up the production line. Ultimately, this resulted in lower prices for finished goods.

So just as with Bessemer and steel rails, when machine tools lowered the cost of interchangeable parts, it led to lower prices for final products, but via a quality increase in the parts rather than a cost decrease:

In the diagram above, the arrow on the right half points to the left but also a bit up. Machines made with interchangeable parts were not only cheaper, they were more reliable and easier to repair. That means the new production method was superior to the old file-to-fit method on both axes—which is why the old one is now obsolete.

Once sufficient economies of scale had been reached, steel hit the same point with respect to other grades of iron, which is why today almost all iron is made into steel:

After some 250 years of iterative improvement, the cost-quality frontier has been shifted so far for so many goods that we enjoy both greater quality and lower cost on pretty much everything we buy. But to get there required navigating a subtle, winding road traversing both axes in different ways at different times.

Original post: https://rootsofprogress.org/cost-quality-and-the-efficient-frontier